What is Ceramic Foam?

Ceramic foam is a skeletal material with a rigid, highly porous and permeable structure; all Duocel foams have controlled density of material per unit volume.

Our most popular ceramic foam is silicon carbide(SiC). Duocel® SiC foam is produced by vapor depositing silicon carbide on our RVC foam.

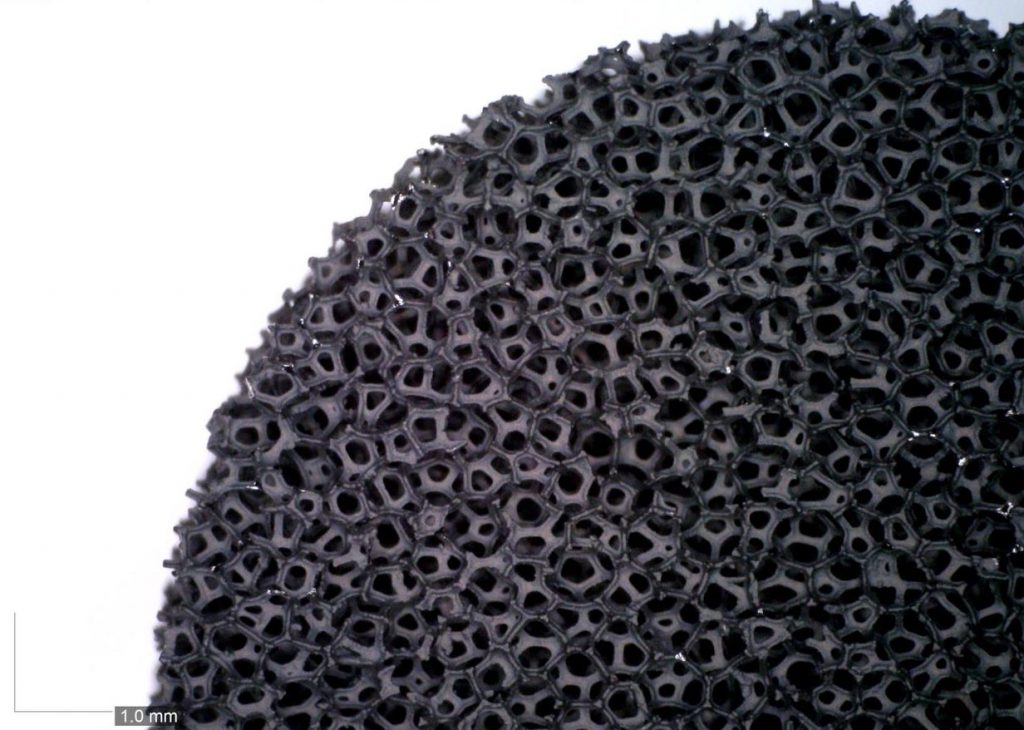

SiC foam, like all of our foam, is open cell, or reticulated foam. This allows for superior liquid flow, low pressure drop and energy absorption for a variety of applications. The matrix of cells and ligaments is completely repeatable, regular, and uniform throughout the entirety of the material.

Most properties of the SiC foam are dictated by the silicon carbide due to its significantly higher volume fraction, its higher elastic modulus and the geometry of the SiC ligaments.

Mechanical Characteristics of Duocel® Silicon Carbide Foam* (10-12% SiC Density 100 Pores Per Inch (PPI))

| Compression Strength | 2800 psi | (19 MPa) |

| Ligament Compressive Strength (Flexural) | 1000 psi | (6.9 MPa) |

| Shear Strength | 700 psi | (4.8 MPa) |

| Mohs Hardness | 9 Mohs | |

| Young’s Modulus | 4 × 105 psi | (2.76 MPa) |

| Knoop Hardness (100gm) | 2500 | |

| Poisson’s Ratio | 0.21 | |

Thermal Conductivity

Ceramics such as silicon carbide (SiC) have high thermal conductivity. Because of the high surface area of Duocel® foam, heat transfer to/from fluids flowing through the foam is greatly accelerated.

Duocel® silicon carbide foam is also ideal for use with phase change materials (PCM) because of the large amount of surface area, which increases coupling to PCM.

Please visit our thermal conductivity page in the technical data section for a more in depth explanation of how materials and properties effects the thermal conductivity of Duocel® foam.

Electrical Conductivity

Duocel® ceramic foam can be used in electrochemical processes that require low electrical and fluid flow resistance. This is in stark contrast to most ceramics, which do not conduct electricity. This is attributable to the reticulated vitreous carbon core encapsulated within the ceramic that has high electrical conductivity.

Duocel® supplements its strength in this type of application with its increased ability to withstand extreme temperatures.

Please visit our electrical conductivity page in the technical data section for a more in depth explanation of how materials and properties effects the electrical conductivity of Duocel® foam.

For Duocel® ceramic foams weight it is exceptionally strong. This strength is also extended to high temperatures. On top of that SiC is very scratch resists at 9 Mohs.

Stability

Max Use (Inert/Reducing) | 3500°F | (1900°C) |

Oxidation Resistance | 2500°F | (1350°C) |

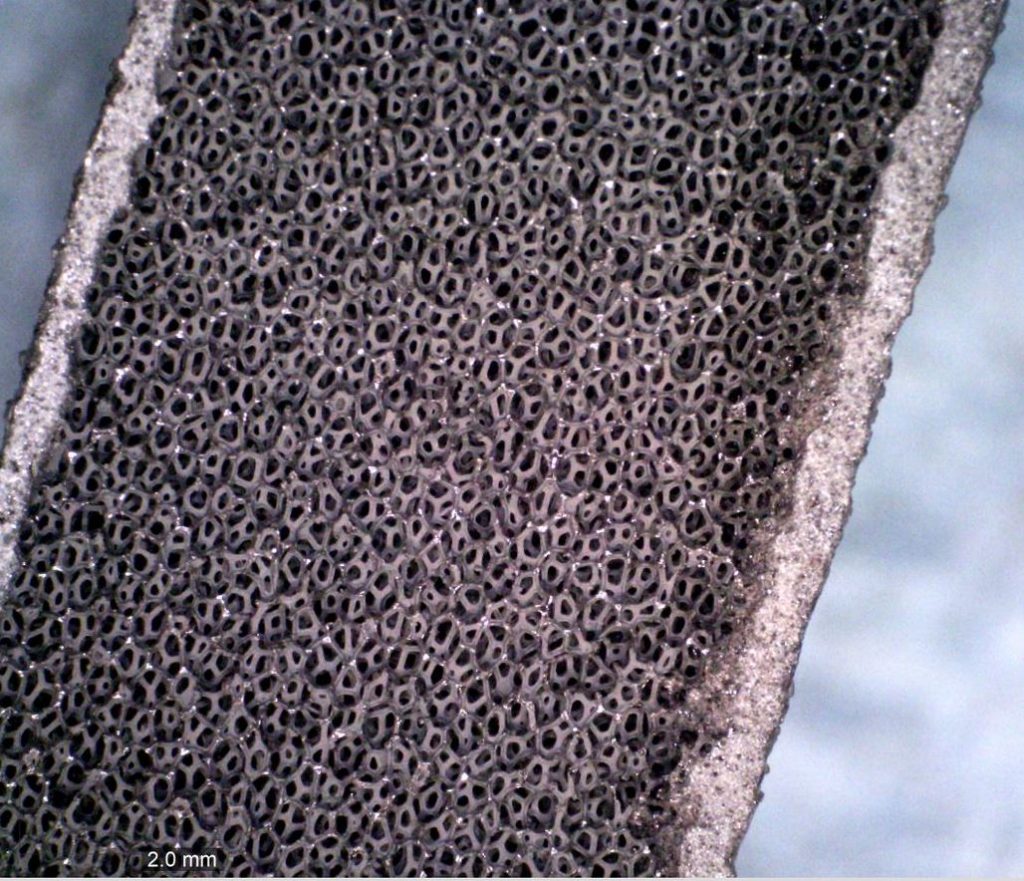

Size

Our ceramic foam can be made up to 1” thick at 100 PPI. Larger pore sizes can be made thicker. Please contact us for more info.

Corrosion resistance

Duocel® silicon carbide foam resists oxidation up to 2500F.

Because of the open cell nature of our foams, a cooling agent, gas or liquid, may be passed through the foam to allow faster heat dissipation than solid structures.

SiC foam also has high resistance to acid corrosion.

It has a hardness that reduces the mechanical wear of the surface of the foam.

Silicon Carbide Foam Magnified 15.1x

Characteristics

- Low Density

- High Strength to Weight Ratio

- High Surface area to Volume Ratio

- isotropic load response

- controlled stress-strain Characteristics

General Properties

| Density Range | 4-30% (0.2 – 1.0 g/cm3 for Duocel® SiC foam) |

| Max Compression | Up to 10x (compressed foam produces orthotropic properties due to the cells being compressed in the thickness direction) |

| PPI Available | 5, 10, 20, 30, 45, 60, 80, 100 |

Download More Information:

Silicon Carbide Foam

Skinned Silicon Carbide Foam Cross Section with solid SiC on both sides

All of our materials are proudly 100% Made in the USA.