What is a Foam Carbon Dioxide (CO2) Scrubber?

A foam CO2 scrubber is a system designed to reduce or remove the amount of carbon dioxide in an air flow stream.

In one application area, carbon dioxide scrubbers are essential to reduce environmental impact from the exhaust of industrial processes.

Alternatively, but employing the same functionality, they are used to allow humans to breathe in environments that have limited oxygen, such as outer space or under water. A human cannot survive in an enclosed or oxygen-limited environment because our bodies inhale the available oxygen and exhale carbon dioxide as a byproduct, which is toxic to rebreathe.

A diver’s rebreather system is an example technology that employs a foam CO2 scrubber, allowing divers to stay underwater longer by processing their exhaled carbon dioxide in a closed-loop system that replenishes fresh oxygen.

Similar technology is used in space, where systems within an astronaut’s suit reject the carbon dioxide they exhale, allowing them to continue breathing oxygen from a supply tank.

Why use Duocel® foam in a Carbon Dioxide Scrubber?

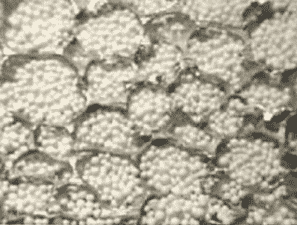

Duocel® foams are valuable in supporting carbon dioxide scrubbing technology because the open-celled structure acts as a support matrix for the material media that performs the scrubbing function as a chemical reaction. Additionally, the solid ligament foam structure has excellent thermal conductivity that is necessary to process any heat generated from scrubbing the carbon dioxide.

For example, the open pores of a Duocel® aluminum foam can be filled with a sorbent material (such as amine powder) which is commonly used to adsorb (or grab onto) carbon dioxide. The drawback of amine powder is that it heats up as it processes carbon dioxide, and if it gets too hot it reverses the adsorption of carbon dioxide and actually releases it instead of continuing to adsorb it. Duocel® foam can help take advantage of this presumable drawback.

An efficient design utilizing Duocel® foam consists of two separate, but identical chambers containing a sorbent material impregnated within the open pores of the metal foam structure.

The two chambers have identical functionality, but they switch roles periodically as carbon dioxide is processed.

The first chamber adsorbs carbon dioxide until the sorbent gets too hot to effectively process carbon dioxide. The flow then switches to allow the first chamber to desorb (or expel) the unwanted carbon dioxide while the second chamber begins adsorbing from the flow stream.

The foam helps facilitate this switch quickly, because the complex matrix of solid ligaments with high surface area draws the heat out of the powder, resetting it for the next cycle of adsorption.

The use of Duocel® in this design also enables a more compact and efficient system by reducing the required volume of sorbent to scrub CO2, further reducing the weight of the assembly. NASA has relied on Duocel® aluminum foam for the development of several iterations of their Rapid Cycle Amine (RCA) technology.

This technology is utilized as a foam CO2 scrubber and humidity removal system within the portable life support system of an astronaut’s space suit.

Why ERG?

ERG has designed, developed, and delivered CO2 scrubbers for NASA and other space companies. ERG has the experience and engineering expertise to precisely adjust the Duocel® parameters to meet the thermal and structural requirements of a wide range of CO2 removal needs. ERG has a 50-year history of making quality Duocel® material and is certified to AS9100 Rev D. ERG is a vertically integrated company focused on customer service and turning ideas into production parts.