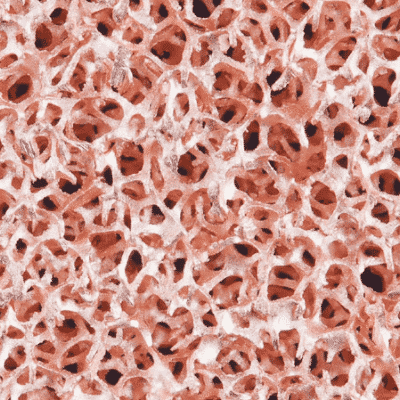

What is Copper Foam?

Copper foam is a rigid, three-dimensional network of interconnected copper ligaments that form cells with open pores. Duocel® Copper Foam contains completely solid ligaments (as opposed to sintered or hollow ligaments) which makes it stronger and more thermally conductive. Its properties are fully customizable, which allows its performance characteristics to be optimized for a broad range of applications. It is commonly used in applications that benefit from very high thermal conductivity and surface area, and from the nature-mimicking morphology of the rigid cellular structure.How is it used and what are its advantages?

Duocel® Copper Foam, also known as foamed copper, is primarily used in applications with high thermal performance requirements, such as heat exchangers, that exceed the capabilities of Duocel® Aluminum Foam. Some of its advantages are listed below. For more examples and information, please refer to the Applications section.

- High thermal conductivity

- High surface area per unit volume

- Creates turbulence in flowing fluids which minimizes boundary layers and promotes mixing to enhance thermal performance

- Custom conformal shapes/geometries to optimize size and weight

How is Duocel® Copper Foam specified and customized?

Duocel® Copper Foam is defined by the following properties:

|

Configuration Property |

Standard Option(s) |

Non-Standard Option(s) (Available on a limited basis or by special order) |

|

Copper Alloy |

C10100 |

N/A |

|

Pores Per Inch (PPI) |

5, 10, 20, 40 |

N/A |

|

Relative Density |

8-12% |

Relative densities less than 8% and greater than 12% |

|

Compression Factor |

Uncompressed, 2X, 3X, 4X, 5X (up to approximately 50% relative density) |

6X+ depending on starting relative density and starting size (up to approximately 70% relative density) |

It can be further customized by the following options:

|

Option |

Description |

|

Coating |

Surface coatings can be applied to enhance or augment the foam’s properties and protect against corrosion. |

|

Joining |

Duocel® Copper Foam can be joined to other components. Joining methods include, but are not limited to: – Adhesive Bonding – Mechanical Fastening – Interference and Thermal Fit – Soldering – Vacuum Brazing |

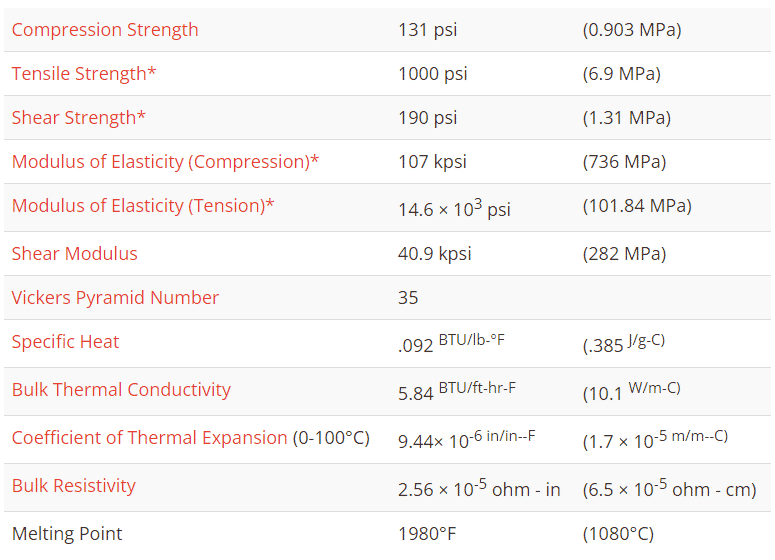

What are its physical properties?

Duocel® Copper Foam has many of the same properties as the parent copper alloy. Its open celled structure, however, does give it unique and customizable characteristics, such as compression strength and surface area. Please refer to the Technical and Applications sections for further details.

Example Physical Characteristics of Duocel® Copper Foam (8% Relative Density):

What are the size limitations?

Duocel® Copper Foam is typically made in starting panel sizes of approximately 3in x 3in x 0.5-1in (76mm x 76mm x 13-25mm). Larger parts can be made by combining multiple pieces or by creating a custom starting size.

There are also limits to how small or thin a part feature can be because cutting the open celled structure too small/thin results in no connected ligaments to hold the material together. The below table contains the standard minimum dimensions of uncompressed foam. Smaller dimensions and features are possible – contact us to determine feasibility for your requirements.

|

PPI |

Standard Minimum Dimension |

|

5 |

0.35in (8.9mm) |

|

10 |

0.25in (6.4mm) |

|

20 |

0.20in (5.1mm) |

|

40 |

0.15in (3.8mm) |

Can it be fabricated to my custom shape/geometry?

Yes. Much like solid copper, Duocel® copper foam can be machined to your unique shape and dimensional requirements. Extra care must be taken for very small and tight-tolerance part features that can be impractical to manufacture or inspect (e.g., small holes, sharp edges or small radii, precise angles, etc.).

Can it be added as a part in an assembly?

Yes. Duocel® copper foam can be integrated into an assembly or system by joining (such as adhesive bonding and brazing), interference and thermal fits, and mechanical fastening. Foamed copper can make up an entire part, or just a small piece of a large system, such as a battery box with a foam flame arrestor.

How do I purchase samples of Duocel® Copper Foam?

Please visit an appropriate distributor, or contact us directly to discuss your application and request samples. In the United States, you may place your order online with a credit card at duocelfoam.com.

Characteristics

- Low Density

- High Strength to Weight Ratio

- High Surface area to Volume Ratio

- Isotropic load response

- Controlled stress-strain Characteristics

- Can be Heat Treated

- Brazable

- Can be coated and plated