What are liquid cold plates?

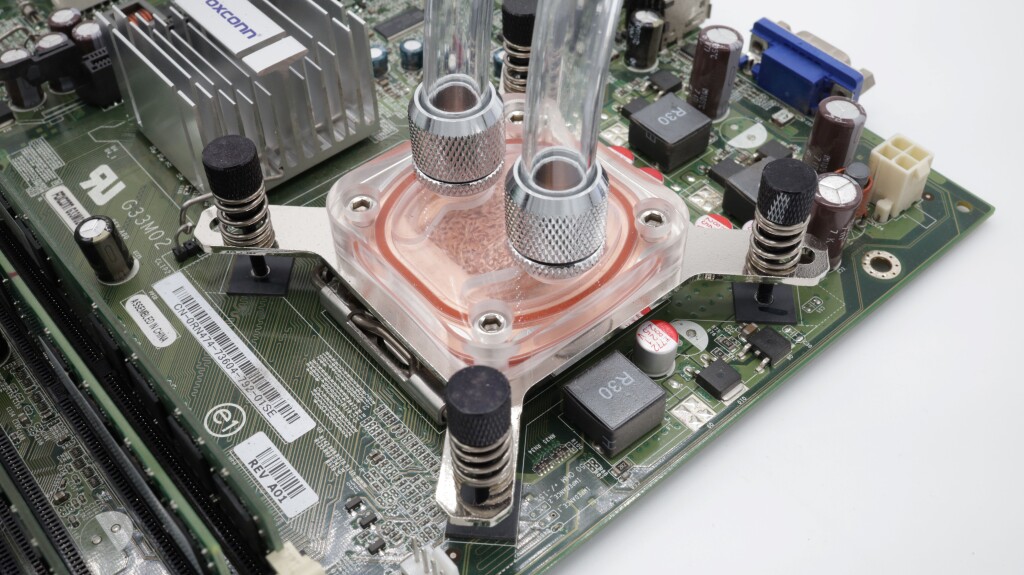

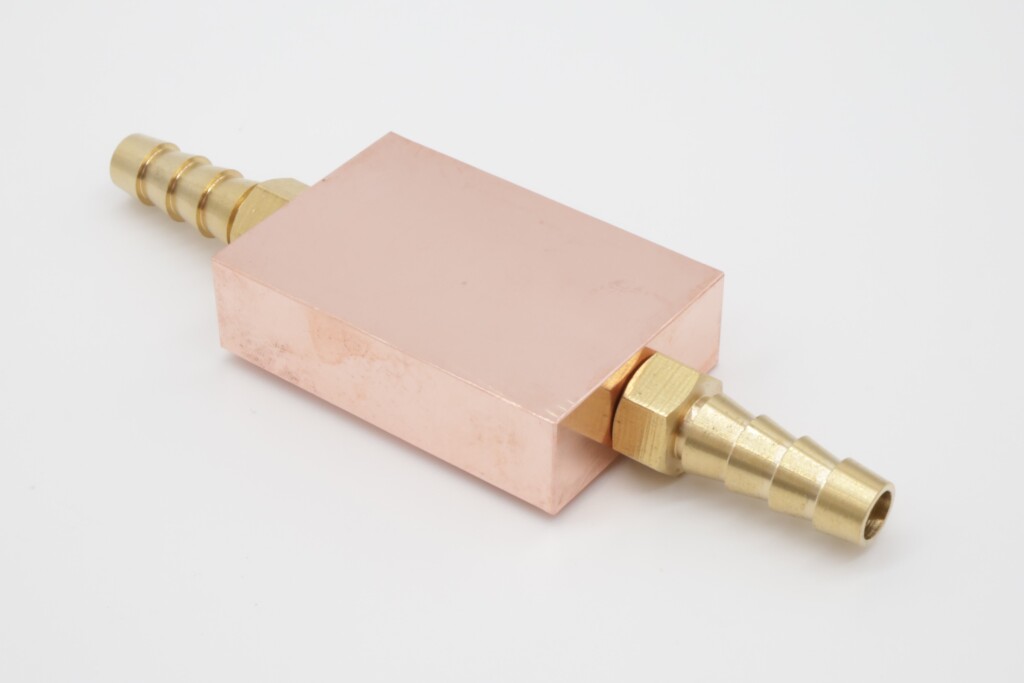

A liquid cold plate attaches directly to a heat-producing object, and then chilled fluid is flowed through it to cool the object. To increase performance, cold plates are typically filled with an extended surface, such as fins, microchannels, or metal foam. Cold plates may be made out of aluminum, copper, or another material with high thermal conductivity.

Why use foam-based liquid cold plates?

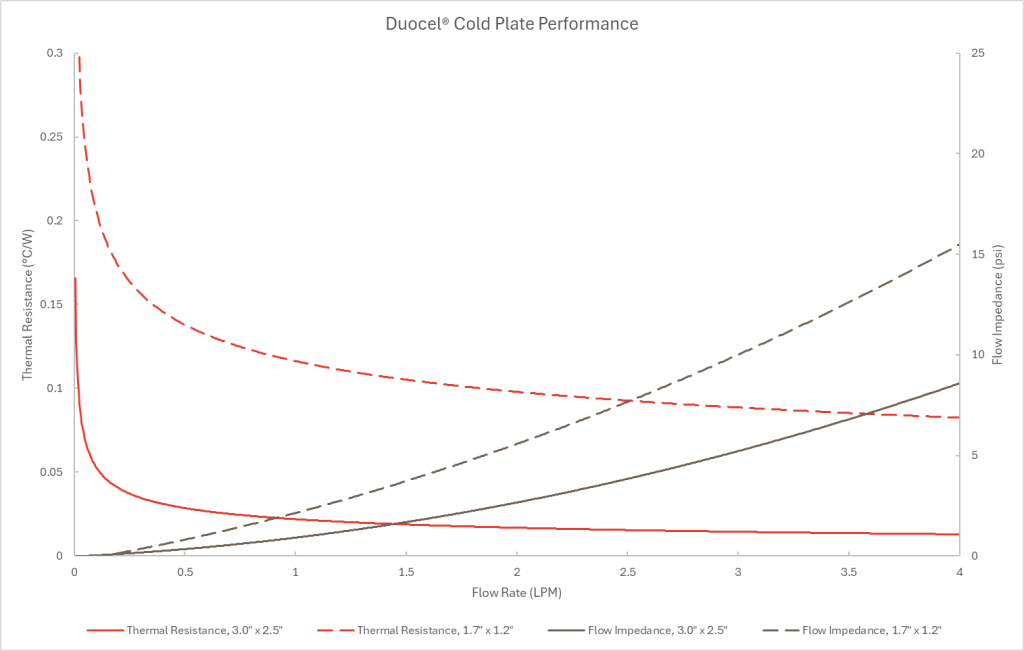

Metal foam works like a fin structure to distribute heat away from the base of the cold plate and into the cooling fluid. Unlike fins, however, Duocel® foam structures encourage mixing, disrupting the thermal boundary layer and enhancing thermal performance.

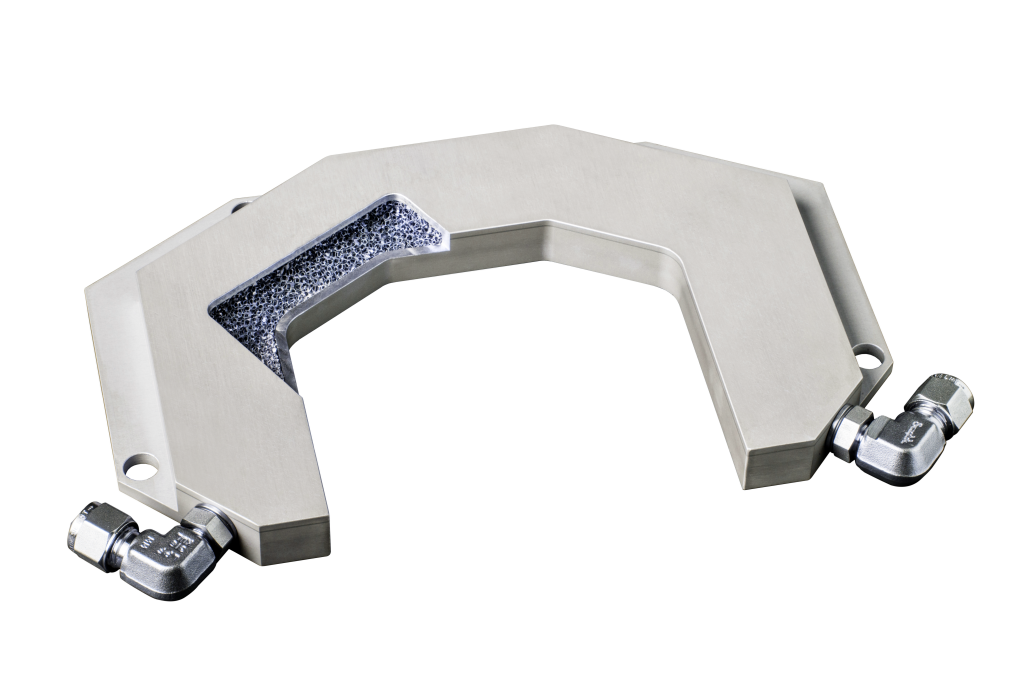

Foam’s unique structure also offers a major advantage for the design and manufacture of conformal cold plates, since fluids can flow through foam in any direction.

How do I order a foam cold plate?

Contact us with some details about your thermal needs, and our engineering team will choose a suitable design or work with you to create something custom.