ERG Aerospace Corporation

Established in 1967

- AS9100 Certified Quality Management System

- Comprehensive In-House Testing Capabilities

- 100 Skilled Employees

- 100% U.S. Made

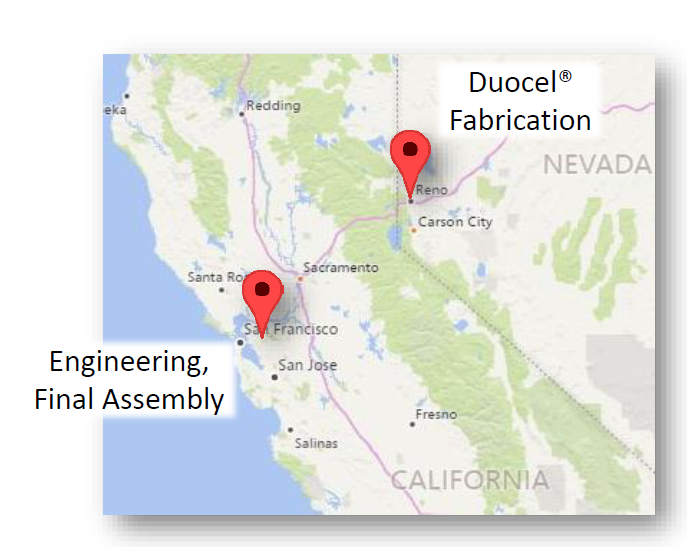

- Nevada: Proprietary Foam Material

- California: Finished Products

- Certified Small Business (NAICS 336412)

Teamwork

At ERG we know that no job gets done without a team. We challenge cross-functional teams to work collaboratively. Together, we strive to make a positive impact and have fun while doing so.

Values

Integrity

We always strive to do what’s right and are accountable for our actions.

Customer Service

We are committed to exceeding our customers’ expectations by understanding their needs, maintaining open lines of communication, and delivering high quality products on time.

Innovation

We must wisely use our unique materials and expertise to turn our ideas and technologies into high performance design solutions.

Respect

We understand that our success is built on respect for our people, our customers, our technology, and the environments in which we work.

History

Founded in 1967, ERG Aerospace Corporation has been manufacturing open-celled, solid ligament metal foams called Duocel®. Since then, ERG Aerospace Corporation has been producing foamed metals, carbons, and ceramics for the aerospace, defense, semiconductor manufacturing, biomedical, and scientific industries.

Up until the mid-1990’s, the majority of ERG’s business was sequestered for military applications and included the design and manufacture of critical foam components for reconnaissance satellites, nuclear weapons, ICBMs, and other aerospace systems. With the end of the Cold War, the advanced design and manufacturing technologies that ERG had perfected were then made available for commercial, scientific, and non-classified military applications.

Our primary facility has been in Oakland, CA since 1967, and in 2017 we added another facility for manufacturing operations in Sparks, NV. On January 1, 2022 ERG officially moved its corporate headquarters to Nevada; the California facility will continue to focus on production, engineering, R&D, and precision manufacturing.

ERG is a proud member of the Service-Disabled Veteran Owned Small Business Program.

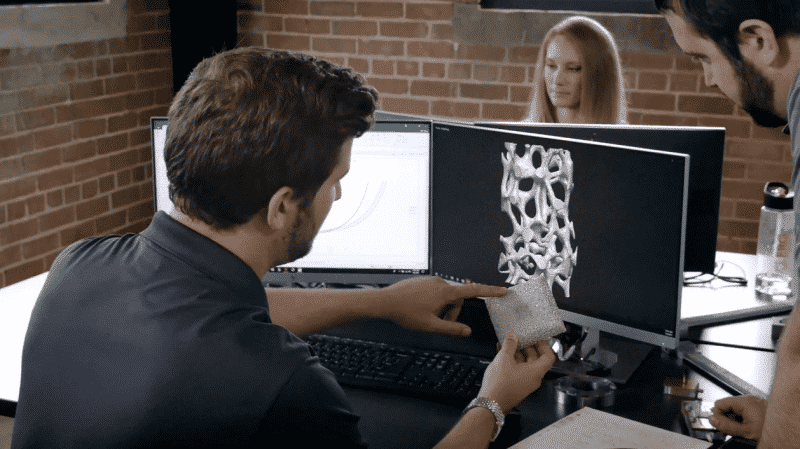

Engineering

ERG has amassed a great deal of engineering mastery over the past 50 years, expertise in both designing and manufacturing Duocel® foam metal components. Our engineers can design and optimize Duocel® foam components for performance and manufacturability in a broad variety of applications.

For example, we have detailed thermal models for predicting and optimizing the performance of Duocel® metal foam heat exchangers. We have mechanical properties test data that can be used to calculate and predict the performance of Duocel® foams for impact absorption and structural applications. If you contact us, our engineers can quickly determine if Duocel® foam components would be viable in your particular application.

Duocel® is available in a variety of materials including carbon and metal foams.

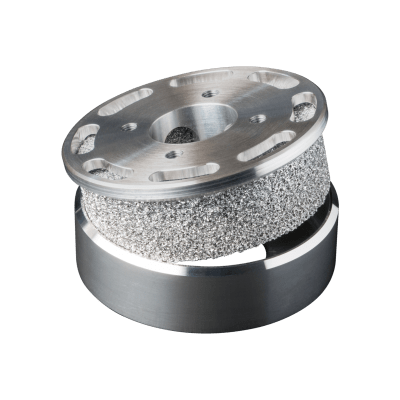

Duocel Air-Oil Separator

Bonding and Brazing

It is possible to bond Duocel® products utilizing conventional epoxies and adhesives. Such bonding agents must be compatible to the Duocel® base material and its finished operating environment. Bonding is considered a cost effective alternative to brazing.

Brazing is common among our thermal management products to increase their heat transfer efficiency. Specialized brazing techniques and processes are necessary to ensure the highest quality in our products.

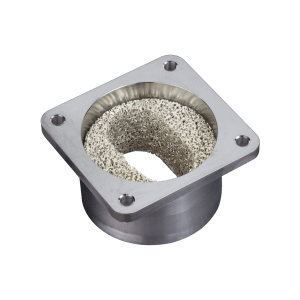

Duocel Heat Exchanger

Heat Treating

Duocel® metal foams are available in many heat treatable conditions that are derived from the parent material alloy. For example, ERG Aerospace’s general practice is to provide Duocel® Aluminum in a T6 condition to maximize the strength and durability of the ligaments.

Duocel Propellant Reinforcements

Machining

Our dedicated Duocel® foam machine shop covers over 20,000 sq. ft., and is comprised of both manual and CNC machines. Precision machinery coupled with decades of experience by our machinists assures the highest quality Duocel® components and assemblies. Our experience and knowledge in machining open-celled metal foams is unmatched by anyone in the world. We also maintain the unique ability to have our engineering staff co-located in the same building allowing our engineers the flexibility to ensure the Duocel® components meet your required performance criteria.

Duocel® foams are unique materials which require special proprietary fabrication and manufacturing processes that ERG Aerospace corporation has developed over the last 50 years. We work with our customers to define the performance requirements and optimize the Duocel® component design. We then perform the fabrication and machining to ensure the product meets your quality and performance requirements. ERG’s basic and QA systems are based on and certified to AS9100 Rev D, which is the US aerospace version of the international standard ISO 9001. For this reason, we do not sell Duocel® foams in raw or bulk form, but only as finished end item components. This ultimately saves everyone time and money, and results in a superior cost-effective product.

Duocel Energy Absorber

Plating and Chemical Films

Duocel® foam metals are capable of taking on additional plating or chemical film. Plating is used to increase the primary foam’s corrosion resistance, surface finish, thermal transfer properties, and electrical conductivity. Common metal plating includes nickel, gold, silver and platinum. Plating also reduces the cost of having to manufacture the primary foam in an expensive alloy.

Chemical film coatings and anodized foam are also utilized when additional environmental protection is desired such as in space flight applications.

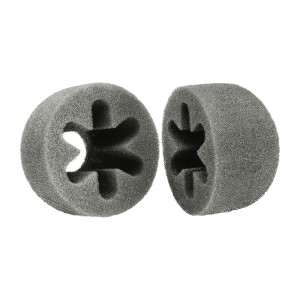

Duocel Electrical and Wind Shielding Microphone

Testing

There are many Non-Destructive Testing (NDT) and Destructive Testing (DT) methods that can be employed to quantitatively characterize the Duocel® foam materials. Some of these tests include airflow, stress/strain, corrosion, X-ray, filtering, salt and leak testing.

Duocel Energy Absorbing Pyramid