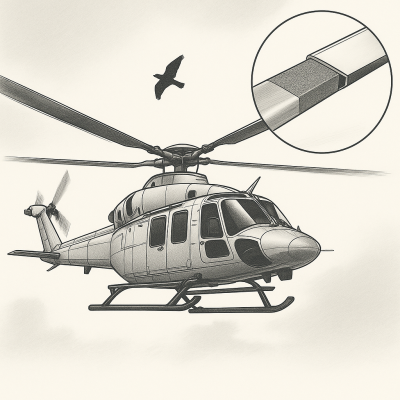

How can metal foam reduce aircraft damage from bird strikes?

Open cell metal foams provide advanced protection from bird strikes damaging aircraft by absorbing and dissipating the energy of an impact – shielding rotors, propellers and leading edges without reducing performance or adding weight.

Bird strikes are a leading cause of damage to aircraft rotors and propellers. When a bird collides with a fast-spinning blade, the impact forces can lead to severe structural damage, posing a risk to flight safety, increasing maintenance costs, and causing unplanned downtime.

In 2023, there were approximately 19,400 reported bird strikes at 713 U.S. airports. Additionally, U.S. air carriers reported 5,100 strikes at foreign airports. The number of reported strikes has been increasing, with 17,190 strikes reported in 2022, according to the FAA

Lightweight, customizable, and proven in aerospace applications, Duocel® Foam helps keep your aircraft flying safer and longer.

How does metal foam protect rotors and propellers to reduce bird strike damage?

Metal foam protects aircraft from bird strikes by providing exceptional energy absorption — ideal for safeguarding rotating components like rotors and propellers:

- Absorbs the kinetic energy of bird impacts, reducing blade deformation and preventing catastrophic failure.

- Maintains structural integrity of propellers and rotors even after high-speed bird strikes.

- Preserves aerodynamic performance and blade balance.

- Greater resistance to crack propagation

- Higher retention of aerodynamic efficiency

- Enhanced compliance with aviation bird strike standards (e.g. FAA/EASA CS 29, CS 25, FAR 33)

Engineered for Aerospace

- Advanced Noise Attenuation – Reduces cabin and structural noise — especially valuable in urban air mobility (UAM), eVTOL, and next-gen aircraft where acoustic performance is a key design constraint.

- Passive Thermal Management – Functions as a passive heat exchanger — helps maintain critical temperature thresholds for avionics, sensors, and electronic subsystems.

- Exceptional Material Compatibility – Bonds readily with aerospace-grade materials such as carbon fiber composites, nylon, titanium, and aluminum — enabling lightweight, integrated system designs.

- Low density – As low as 3% of the solid metal – adds minimal, if any weight to rotors and propellers.

Ready to improve bird strike protection?

Our team will help you design and integrate Duocel® Foam into your blades for superior performance and safety. Contact us to learn more!

Customized bird strike protection

- Tailored to match blade design and bird strike mitigation requirements

- Seamless integration with rotors and propeller blades

- Easily integrated into leading edges, tips, or as a protective internal structure

- Compatible with modern composite blades as well as metal blade designs

- Durable, corrosion-resistant and long-lasting

- Resists fatigue, vibration, corrosion, and extreme temperatures

- Provides long-term bird strike protection with no maintenance and no reduced performance

Protection is critical for:

- Helicopter rotors (main & tail)

- Propeller’s on turboprop aircraft

- Drone & UAV rotors

- Fan blade protection in jet engines

- eVTOL Aircraft

Download White Papers:

Duocel® Foam for Bird Strike Mitigation in Aerospace Structures

Why choose ERG Aerospace for bird strike protection?

- AS9100 Certified

- Fully Customizable

- Over 50 years of Experience

- Made in the USA