Electrical Conductivity of Duocel® Foams

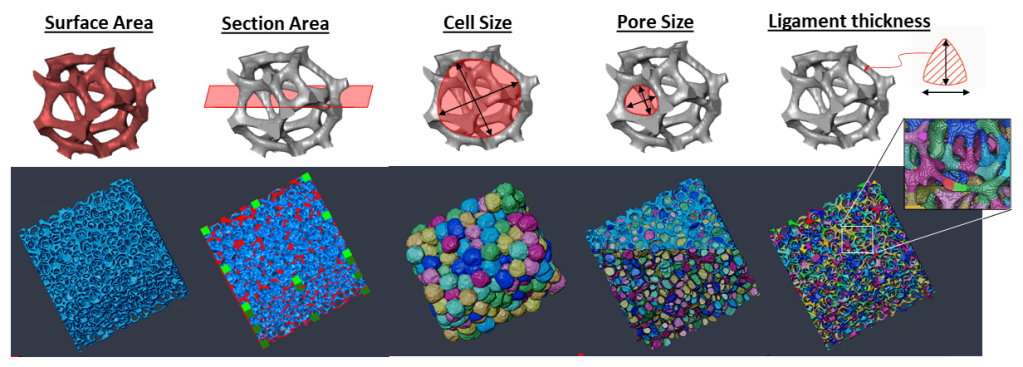

Duocel® foams are widely utilized in advanced engineering applications, particularly as porous electrodes in electrochemical systems such as batteries, fuel cells, and electrochemical sensors. In these applications, predicting the electrical conductivity of the foam structure is a valuable design consideration, as it directly influences the efficiency of electron transport through the material.

Basic Electrical Conductivity Equation

The bulk electrical conductivity of Duocel® foams—particularly under conditions of low amperage and direct current (DC)— is expressed as:

Where:

- Csolid ligaments = Effective electrical conductivity of the 3D ligament network under low amperage DC conditions (units: S/m or siemens per meter)

- Csolid = Intrinsic electrical conductivity of the parent solid material from which the foam is made (e.g., pure aluminum, copper, nickel)

- Relative Density = Foam density as a fraction of the solid material density (expressed in decimal form, e.g., 10% relative density = 0.10)

- 0.33 = Empirical geometric coefficient accounting for the foam’s three-dimensional tortuous structure

Significance of the 0.33 Coefficient

The 0.33 coefficient is not arbitrary. It arises from both:

- Experimental measurements of electrical conductivity across various foam samples

- Conceptual geometric modeling, where the foam is approximated as a three-dimensional orthogonal array of pin fins.

In such an analogy, one can imagine a simple lattice of pin-shaped struts aligned along the x, y, and z axes. Since the current has no preference for direction in an isotropic foam, only about one-third of the conductive pathways are effectively aligned with any given direction of applied current. The other two-thirds contribute less directly due to their orientation, which reduces the effective path for current flow in the measured direction.

Example Calculation

Let’s consider an example using aluminum foam with a known electrical conductivity and relative density:

- Csolid =3.5 × 107 S/m (for pure aluminum)

- Relative Density = 0.08 (i.e., 8% of the density of solid aluminum)

Using the equation:

This means the foam has an effective electrical conductivity of approximately 924,000 S/m, which is significantly lower than that of bulk aluminum but still sufficient for many electrical applications such as current collectors or heat sinks in electronics.

Important Considerations and Limitations

This equation is a simplified model that assumes ideal conditions and may not capture all real-world complexities. Key limitations include:

- Frequency Effects: This model applies to DC or very low-frequency AC scenarios. At higher frequencies, skin effects and inductive reactance can distort the effective conductivity.

- High Amperage Conditions: At large currents, Joule heating, electromagnetic interactions, and nonlinear material responses can cause deviations from predicted behavior.

- Transient Behavior: The model does not account for transient electrical phenomena, such as switching effects or time-varying voltage inputs, which could lead to dynamic changes in current paths within the foam.

Additional Application Examples

- Battery Electrodes: Duocel® foams are used in nickel-metal hydride (NiMH) or lithium-ion battery designs to support active materials while allowing for current flow through their 3D structures.

- Fuel Cell Diffusion Layers: Their porous yet conductive nature makes them ideal for gas diffusion layers in proton-exchange membrane (PEM) fuel cells.

- EMI Shielding: The ability to control electrical conductivity while maintaining porosity makes Duocel® effective in electromagnetic interference (EMI) shielding enclosures, especially in aerospace applications where weight is critical.