Metal foam has a high specific surface area, and a chaotic ligament structure. The high specific surface area allows for increased contact with the carrying medium. The chaotic arrangement of the fluid passageways in the foam creates turbulence in the carrying medium, thus increasing surface contact and convection. This leads to a more efficient system, in a smaller space.

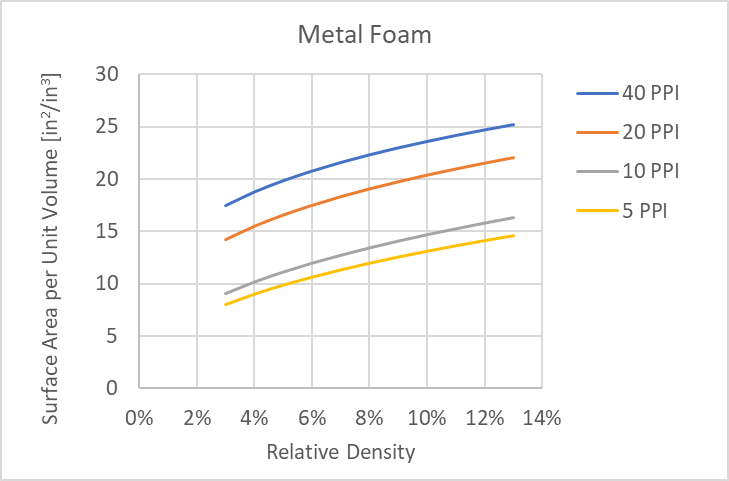

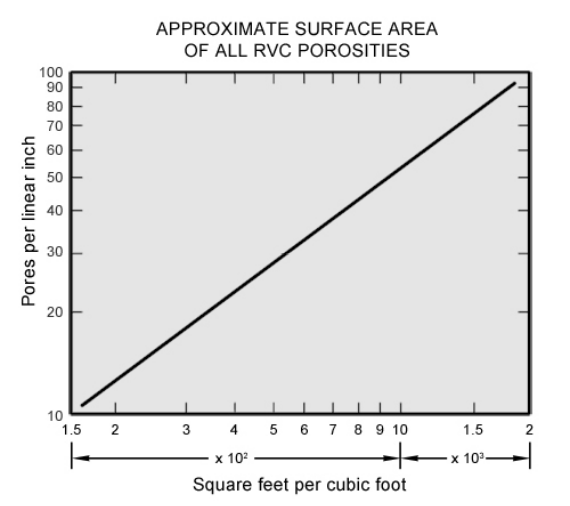

Some foam properties are solely a function of the foam structure and are totally unaffected by the choice of base material. The two most important of these are specific surface area and fluid flow resistance. These properties are influenced primarily by the pore size and secondarily by relative density.

The specific surface area of a foam is the amount of surface area within a given bulk volume of foam. The high specific surface area of Duocel® foam enables smaller, more efficient systems. Specific surface area increases with the foam pore density and relative density. Presented below are graphs of specific surface area as a function of both of these key foam parameters. The data for metal foam was calculated using CT scan data.