What is an Aircraft Air Oil Separator?

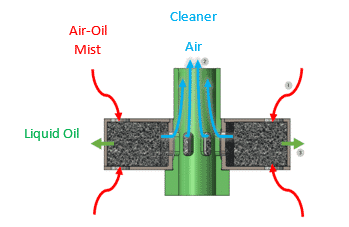

An Aircraft Air Oil Separators (AOS) is a rotating component used in gas turbine powered aircraft and high-performance vehicles. It uses a robust filter to convert the oil mist inside a gearbox back into liquid oil and clean air; the liquid oil is reused for lubrication and clean air exits to the environment. Aircraft Air oil separators, also called de-oilers, are vital components of an engine’s lubrication system design. They help reduce oil consumption, lower emissions, and save money by increasing oil recovery. These devices are also known as centrifugal purifiers / breathers or centrifugal oil filters.

Why is an Air Oil Separator important?

As lubricating oil heats up during engine operation, it can vaporize and create an undesirable mist of fine particles in the clean air stream. To keep the engine operating efficiently, it is important to separate this oil from the air. This is done by forcing the oil-infused air through a path that is more difficult for the oil to navigate than the air. The basic aircraft air oil separator design requires a physical interaction with the AOS structure to help coalesce the finely dispersed oil particles into larger droplets. Because liquid oil is heavier than air, it gets separated out and centrifugal forces help drive the oil toward the outside of the structure where it can be expelled. The clean air is then able to vent through the AOS and out to the environment.

How does Duocel® make a great Aircraft Air Oil Separator?

Duocel® foam makes an excellent aircraft air oil separator or centrifugal purifier material because it is customizable for a high surface area to volume ratio and increased tortuosity, while being light weight with high structural integrity. The high surface area of the interconnected ligaments creates a tortuous path with no clear line of sight through the material, forcing the mist to repeatedly have a physical interaction with the structure for maximum separation potential. Additionally, Duocel® has high structural integrity, allowing it to withstand centrifugal forces at up to 15,000 RPM. Enabling higher shaft rotation speeds further improves the separation efficiency by increasing the velocity of the oily mist.

Another advantage of Duocel® is that it will perform better than traditional designs at all engine operating conditions. Using an aircraft example, a Duocel® foam aircraft air oil separator will significantly reduce oil consumption at engine idle, take-off, cruise, and maximum engine operating conditions. Traditional technology utilizes much more rudimentary structures and therefore can only be designed to target one engine operating condition. This results in oil consumption increasing (meaning more oil is lost from the system) at non optimal conditions. Traditional technologies generally have a simple flow path through the Aircraft AOS, so non-optimal operating conditions do not enable as much interaction, resulting in less oil getting separated out of the two-phase mist.

Duocel® foam can be tailored to maximize the surface area to volume ratio within the design envelope by modifying the structure’s pore size and compression level. The strength can be controlled by modifying the ligaments’ cross section, allowing it to last the life of the gearbox even at high rotational speeds. These factors are controlled to be optimized within the system-level pressure drop requirements, resulting in a Duocel® solution for any gearbox design. Duocel® is unique among metal foams and metal meshes because of its high structural integrity. Many other metal foams have hollow ligaments or incomplete grain boundaries, and thus are not compressible and cannot hold up to high rotational speeds.

Why ERG?

ERG has designed, developed, and delivered over 1000 separators for major engine and gearbox companies, across several gearbox designs. ERG has the experience and engineering expertise to precisely adjust the Duocel® parameters to meet the pressure drop and mechanical requirements of a wide range of designs. ERG has a 50-year history of making quality Duocel® material and is certified to AS9100 Rev D. ERG is a vertically integrated company focused on customer service and turning ideas into production parts.

Performance

- 2000x better oil separation

- Flight proven with over 1000 units delivered across several gearbox designs

- Up to 15,000 RPM and 350°F

- Customizable to system pressure drop

- Housing design to fit range of shaft design configurations

Duocel®

- Maximize Surface Area to Volume with pore size and compression

- Meet mechanical requirements by tuning ligament cross section

Download More Information: