What is a Foam Energy Absorber?

An energy absorber is a material or device that dissipates kinetic energy and is commonly used to protect fragile objects such as sensitive equipment and payloads. A vehicle bumper, for example, is an energy absorber that protects the vehicle’s occupants in the event of a collision/crash. A Duocel® Energy Absorber is typically made from Duocel® Aluminum Foam or Duocel® Carbon (RVC) Foam.Refer to the Energy Absorption page for more technical information.

How does a Duocel® Energy Absorber work and what are its advantages?

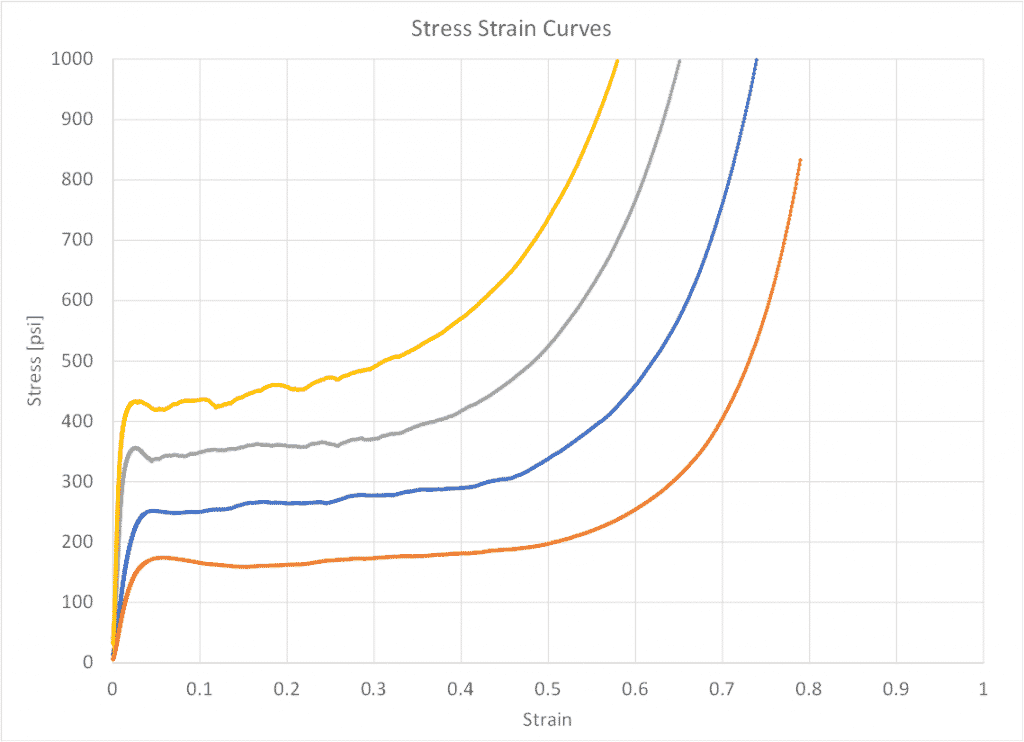

When a force or load is applied to Duocel® Metal Foam, it permanently deforms and compresses; densifying as its pores collapse and its ductile ligaments bend and buckle. Conversely, Duocel® Carbon (RVC) Foam’s ligaments are brittle and crumble under a compressive load.Some benefits of a Duocel® Energy Absorber include:

- High strength-to-weight ratio – Duocel® is lightweight due to its porous structure while maintaining many of the properties, including strength, of its parent material (e.g., aluminum).

- Controlled strength and stress-strain behavior – The properties of Duocel®, such as relative density and heat treat condition, can be tailored for specific mechanical performance requirements.

- Isotropic compression – Duocel® deforms and compresses uniformly regardless of the load/impact direction.

- Resistant to harsh environments – Duocel® is made from robust materials that can withstand extreme temperatures, humidity, chemicals and liquids, atmosphere/vacuum conditions, etc.

- No sharp spike in yield strength – This behavior can be mitigated by adjusting the properties of Duocel®.

- Custom shapes to optimize size and weight – Duocel® can be fabricated to a specific geometry to conform to design requirements.

What are some example applications of a Duocel® Energy Absorber?

Duocel® foam is used as an energy absorber in various industries and applications, including:

- Aerospace

- Aircraft impact protection

- Bird strike protection

- Pyrotechnic hardware containment (e.g., explosive bolts)

- Latch release mechanism containment

- Micrometeoroid shields

- Defense

- Military vehicle seating

- Explosive ordnance disposal (EOD)

- Scientific

- Nuclear material shipping containers

- Instrument protection

- Commercial

- Vehicle crush structures

- Personal protective equipment (PPE)

Why ERG?

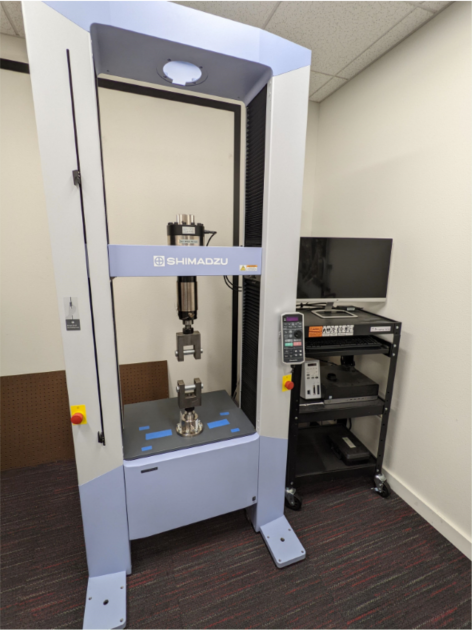

ERG has designed, developed, and delivered numerous Duocel® Energy Absorbers for critical applications. We have the experience and engineering expertise, including an in-house test laboratory and database, to precisely adjust the Duocel® parameters to meet the mechanical and performance requirements for a wide range of designs. ERG has a 50-year history of making quality Duocel® materials and is certified to AS9100 Rev D. ERG is a vertically integrated company focused on customer service and turning ideas into production parts.

Advantages

- Lightweight

- High strength-to-weight ratio

- Customizable strength

- Isotropic compression

- Resistant to harsh environments

- Adjust relative density to control stress-strain behavior – Larger ligament cross section results in a stronger structure

- Custom shapes can control impact area

- Open celled structure significantly reduces unwanted rebound

- Easily integrates into an assembly/system

Download More Information: