What are lightweight metal foam structures?

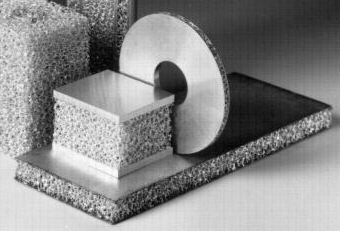

Duocel® Lightweight Structures are solid ligament, open cell foam structures, often with a solid component to increase strength and provide a flush interfacing surface. These structures offer exceptional strength-to-weight ratios and are fully customizable, making them ideal for applications where weight savings and mechanical performance are critical.

Why Choose Duocel® for Lightweight Structural Applications?

Duocel® foam stands out due to its unique combination of properties:

- High Strength-to-Weight Ratio: The open-cell structure ensures minimal weight without compromising structural integrity.

- Customizable Properties: Adjustable parameters like relative density and pore size allow tailoring of mechanical properties to specific application needs.

- Isotropic Behavior: Uniform properties in all directions ensure consistent performance under multidirectional loads.

- Thermal and Chemical Stability: Suitable for extreme environments, Duocel® maintains performance under high temperatures and in corrosive conditions.

- Integration Flexibility: Easily incorporated into assemblies through bonding, brazing, or mechanical fastening.

Applications of Duocel® Lightweight Structures

Duocel® foams are utilized in a wide range of applications where lightweight and high-performance materials are essential:

- Aerospace: Structural components, impact protection, and thermal management systems.

- Defense: Lightweight armor, blast mitigation structures, and structural panels.

- Industrial: Lightweight, high strength support structures are often built from foam sandwich panels. Particularly in high-temperature processing equipment and filtration systems.

- Space: Lightweight components, sensor protection, and micrometeorite protection can be implemented with radiation protection or thermal transfer in a single product!

Customization and Fabrication

ERG Aerospace offers Duocel® foams with customizable features to meet specific design requirements:

- Pore Size (PPI): Available in various pores per inch (PPI) to control permeability and surface area.

- Relative Density: Adjustable to balance weight and mechanical strength.

- Material Selection: Most support structures are built with aluminum foam and supporting panels

Why ERG?

ERG has designed, developed, and delivered numerous Duocel® Energy Absorbers for critical applications. We have the experience and engineering expertise, including an in-house test laboratory and database, to precisely adjust the Duocel® parameters to meet the mechanical and performance requirements for a wide range of designs. ERG has a 50-year history of making quality Duocel® materials and is certified to AS9100 Rev D. ERG is a vertically integrated company focused on customer service and turning ideas into production parts.

Advantages

- Lightweight

- High strength-to-weight ratio

- Customizable strength

- Isotropic compression

- Resistant to harsh environments

Duocel

- Adjust relative density to control stress-strain behavior – Larger ligament cross section results in a stronger structure

- Custom shapes can control impact area

- Open celled structure significantly reduces unwanted rebound

- Easily integrates into an assembly/system