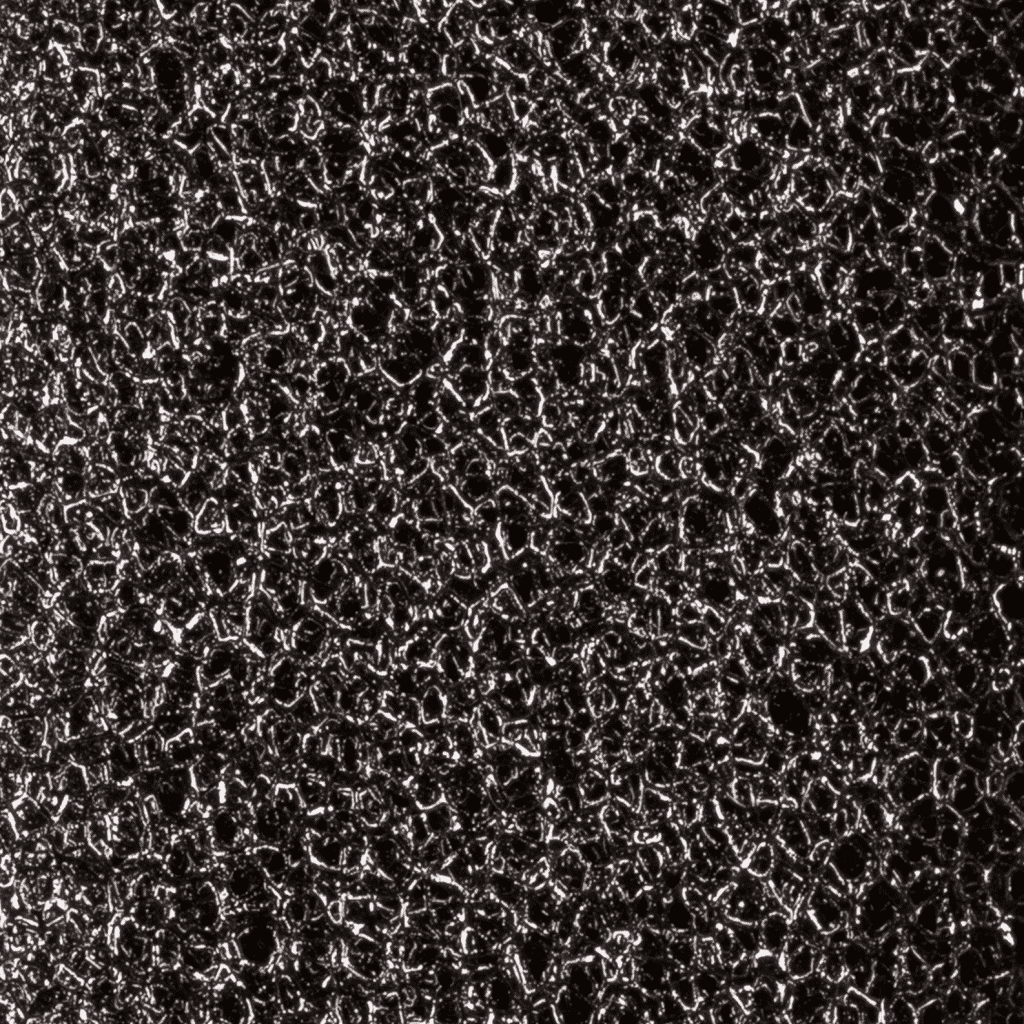

What is Carbon (RVC) foam?

Carbon foam, also known as reticulated vitreous carbon (RVC) foam is a skeletal material with a rigid, highly porous and permeable structure; all Duocel foams have controlled density of material per unit volume.

The matrix of cells and ligaments is completely repeatable, regular, and uniform throughout the RVC foam material.

Physical Characteristics of Duocel® Carbon Foam (3% Nominal Density)

| Compression Strength | 15-75 psi | (0.10-0.52 MPa) |

| Tensile Strength* | 25-50 psi | (0.17-0.34 MPa) |

| Shear Strength* | 4.4×103 psi | (30.3 Mpa) |

| Mohs Hardness | 6-7 Mohs | |

| Modulus of Elasticity (Tension)* | 14.6 × 103 psi | (101.84 MPa) |

| Shear Modulus | 4.4 × 103 psi | (30.3 MPa) |

| Vickers Pyramid Number | 35 HV | |

| Specific Heat | .3 BTU/lb °F | (1.26 J/g °C) |

| Bulk Thermal Conductivity | 0.021 – 0.029 BTU/ft ·hr·°F | (0.033 – 0.050 W/m °C) |

| Coefficient of Thermal Expansion | ||

| (0-100°C) | 1.2 × 10-6 in/in°F | (2.2 × 10-6 m/m°C) |

| (100-1000°C) | 1.8 × 10-6 in/in°F | (3.2 × 10-6 m/m°C) |

| Bulk Resistivity | 12.7 × 10-2 ohm · in | (32.3 × 10-2 ohm · cm) |

| Temperature Limitations | ||

| In air | 600°F | (315°C) |

| Inert environment | 6330°F | (3499°C) |

Thermal Conductivity

Carbon foam has low thermal resistance. Because of the high surface area of Duocel® foam, heat transfer to/from fluids flowing through the foam is greatly accelerated.

Duocel® Carbon foam is also ideal for use with phase change materials (PCM) because of the large amount of surface area, which increases coupling to PCM.

Please visit our thermal conductivity page in the technical data section for a more in depth explanation of how materials and properties effects the thermal conductivity of Duocel® foam.

Crush Strength

When a load is applied to a foam structure, it will initially yield elastically. However, at approximately 4-6% of strain, depending on the sample size, the foam structure will begin to buckle and collapse continuously at a relatively constant stress. Depending upon the initial relative density of the foam, this constant collapse will proceed to approximately 50-70% of strain. At that point, the stress / strain curve will begin to rise as the compressed foam enters the “densification” phase.

The point in the stress / strain curve where it transitions from the elastic to plastic deformation phase defines the “crush strength” of the foam. This is an important mechanical parameter as it is obviously essential to remain below that level for any structure that is being designed to maintain its shape under design load

Please visit our energy absorption page in the technical data section for a more in depth explanation of how materials and properties effects the crush strength of Duocel® foam.

Electrical Conductivity

Duocel® RVC foam is an excellent material for use as a porous electrode. The structure provides both low electrical and low fluid flow resistance. Large current distribution areas are possible due to the enormous amount of surface area of the foam.

Please visit our electrical conductivity page in the technical data section for a more in depth explanation of how materials and properties effects the electrical conductivity of Duocel® foam.

Density

Duocel® Reticulated Vitreous Carbon ( RVC) is made in a 3% relative density (of it’s parent material), or it has 97% void volume. The resulting foam structure is extremely lightweight.

Strength

Duocel® RVC is uniquely strong at elevated temperatures. It also has a high scratch resistance at 6-7 mohs.

Corrosion Resistance

Duocel® carbon foam is composed of one of the most chemically inert forms of Carbon, and highly resistant to intercalation by materials which disintegrate graphite.

Duocel® RVC foam is inert to a wide rage of very reactive acids, bases, and organic solvents. At high temperatures it will form carbides, but is inert to non-carbide forming metals

Sizes

Duocel® RVC foam is manufactured at 3% relative density and is made in a billet size of 6” x 12” x 24”. ERG does have the capability to create larger billet sizes on a custom basis.

Characteristics:

- Low Density

- High Strength to Weight Ratio

- High Surface area to Volume Ratio

- isotropic load response

- controlled stress-strain Characteristics

General Properties

| Density Range | 3% |

| Max Compression | up to 25x |

| PPI Available | 5, 10, 20, 30, 45, 60, 80, 100 |

Carbon Foam can be manufactured with the same density as human bone for bone replacements.

All of our materials are proudly 100% Made in the USA.