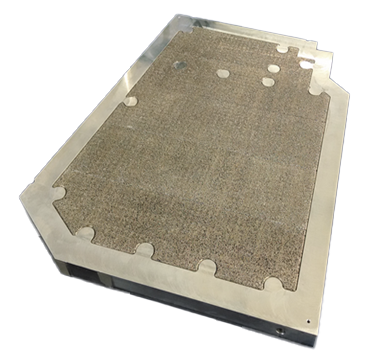

What are PCM Thermal Capacitors?

Phase Change Material (PCM) thermal capacitors work like ice packs to absorb random or cyclical spikes in thermal energy.

The phase change material inside the housing melts (i.e., changes phase) during periods of high heat load and re-solidifies during periods of lower heat load.

This helps even out the spikes in heat load and keeps the whole system at a steady, lower temperature.

PCM thermal capacitors also help absorb heat spikes so that other cooling equipment can be designed with a lower capacity.

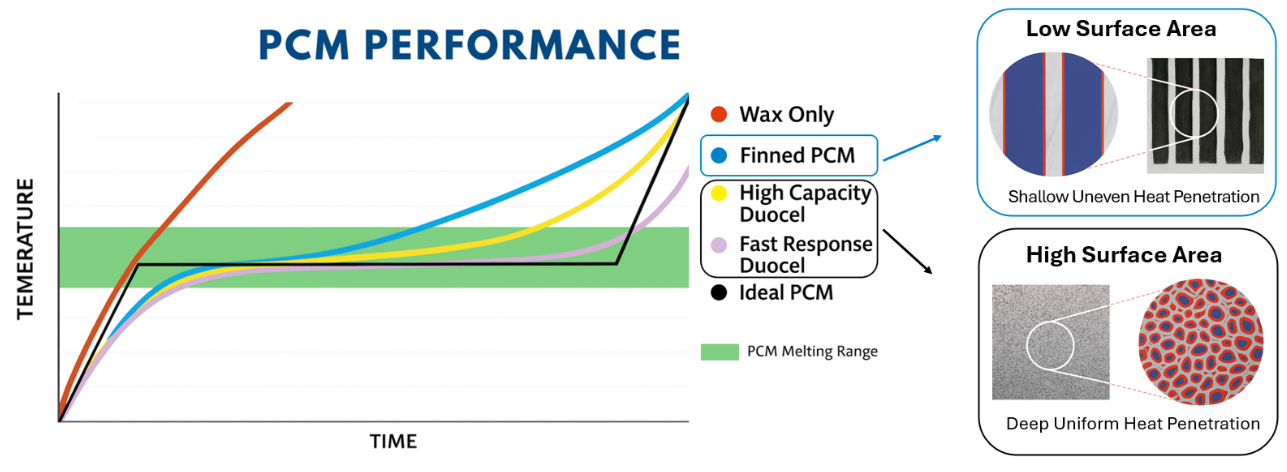

How Does Foam Improve Performance?

- Isothermal Stability – Holds target temp longer

- High Heat Flux – Faster charge/discharge for peak load management

- Quick Response – Cycles up to 20% faster than fins

- Longer Life – Reduces PCM stress for higher cycle counts

- Scalable Design – Tunable for energy density or heat flux needs

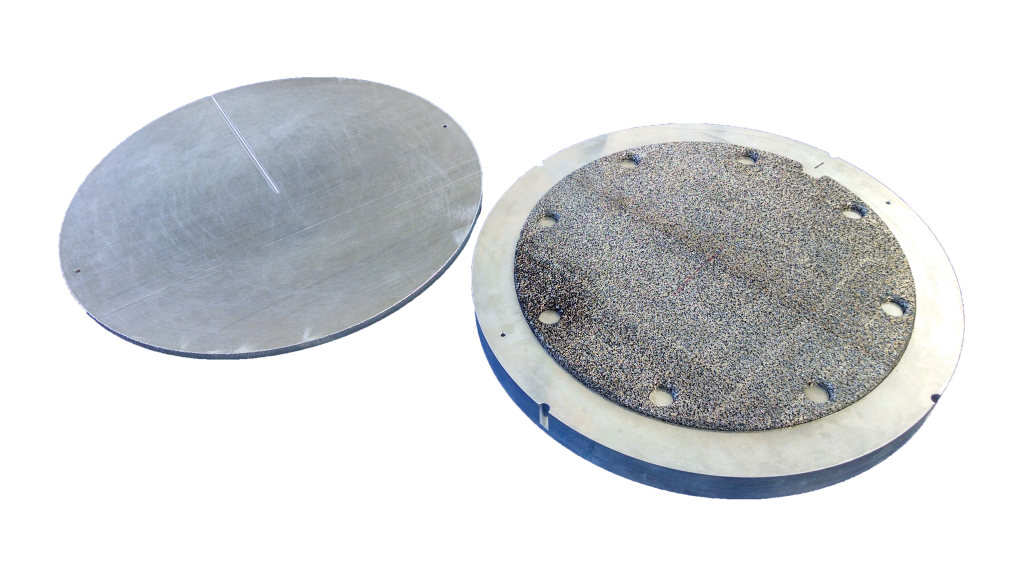

Why use metal foam in PCMs?

PCMs often use paraffin waxes as the phase change material. These waxes melt at the proper temperature for electronics, but they have low thermal conductivity. Duocel® metal foam acts as a matrix to enhance the conductivity of the PCM, resulting in a more complete transfer of heat into the wax. The metal foam structure also helps PCM materials nucleate and re-solidify faster.

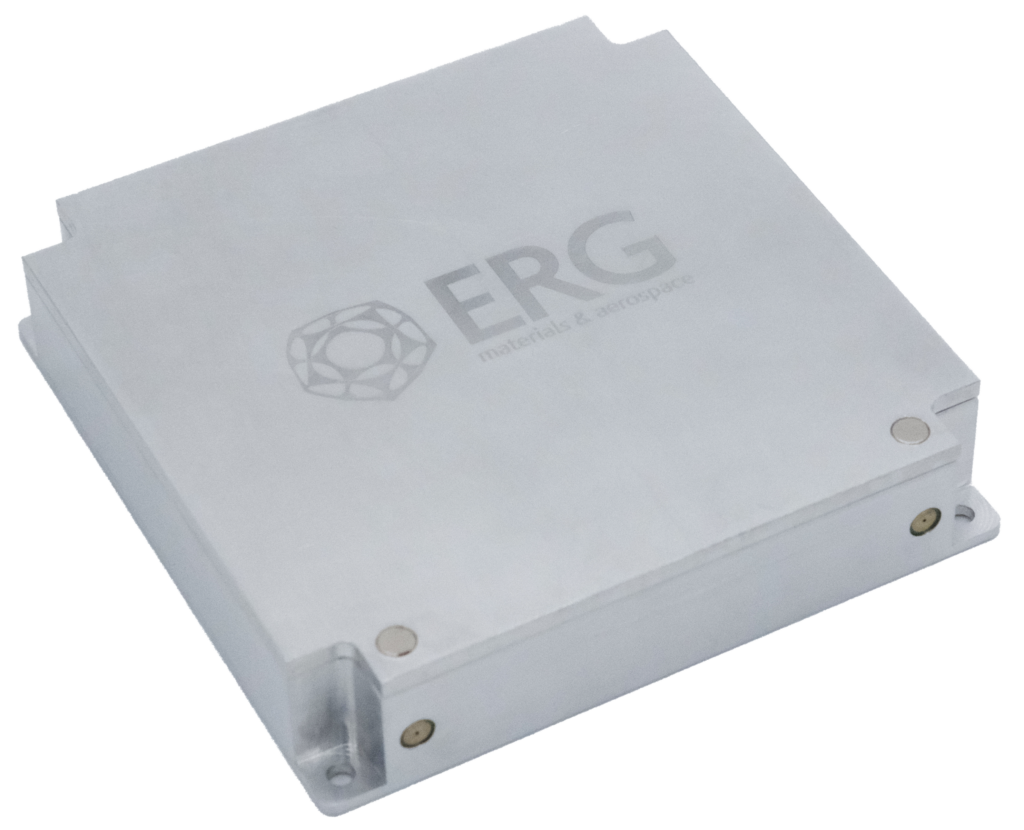

How do I order a PCM thermal capacitor?

Contact us with details about your thermal needs, and our engineering team will choose a suitable design or work with you to create something custom.