What is Duocel® Foam?

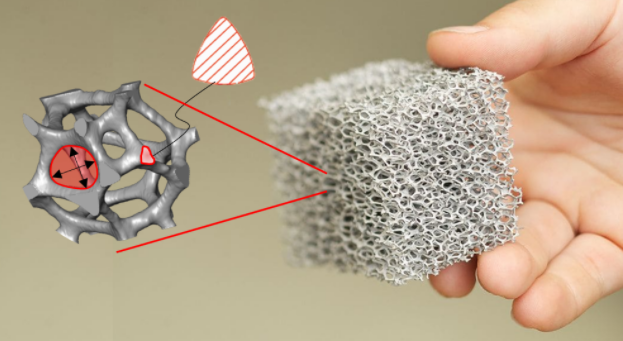

Duocel® is a foam structure comprised of a network of ligaments that form cells with open pores. Duocel® stands apart from many other foams on the market because its individual ligaments are solid, offering strength and reliability, while its pores are open, allowing for fluids to pass through the entirety of the structure. This unique structure makes Duocel® an extremely capable solution for high performance applications that require lightweight, compact, and efficient materials.

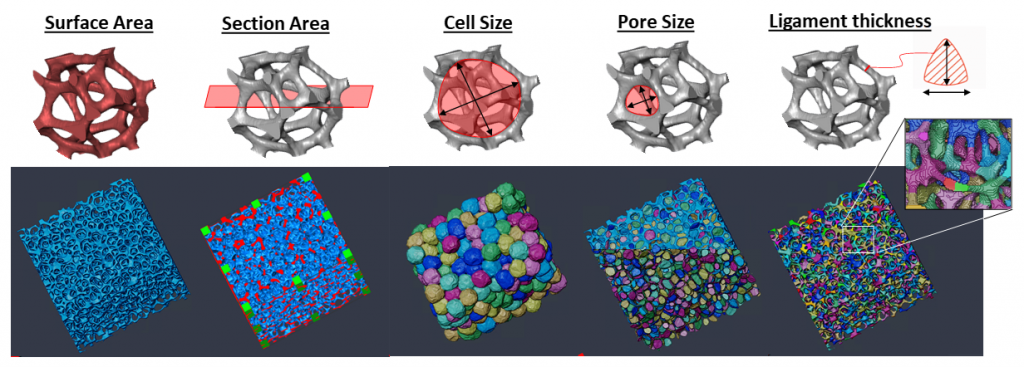

How is open celled Duocel® Foam characterized?

Duocel® foam’s structure is highly customizable to meet a wide range of performance and application requirements. In the simplest terms, ERG controls three main parameters to classify the material and deliver a custom set of properties: first, the base material of the foam structure; second, the pore size; and third, the ligament cross section (specified by relative density).

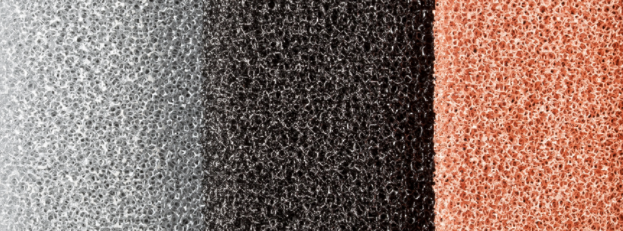

Base Material

The primary variable that will have the largest effect on the performance of the structure is the base material. Duocel® can be made from metals, carbon, and ceramics. The structure exhibits similar material and chemical behavior to its base material. Each category of base material offers unique characteristics and choosing an appropriate base material will drive all other properties.

For example, a design requiring a strong panel to function as an energy absorber might use an aluminum metal foam to deliver customizable compression strength with ductile ligaments for controlled performance. Alternatively, for an application demanding high electrical conductivity compatible with electrolytic solutions, carbon foam will provide the perfect answer.

Pore Size

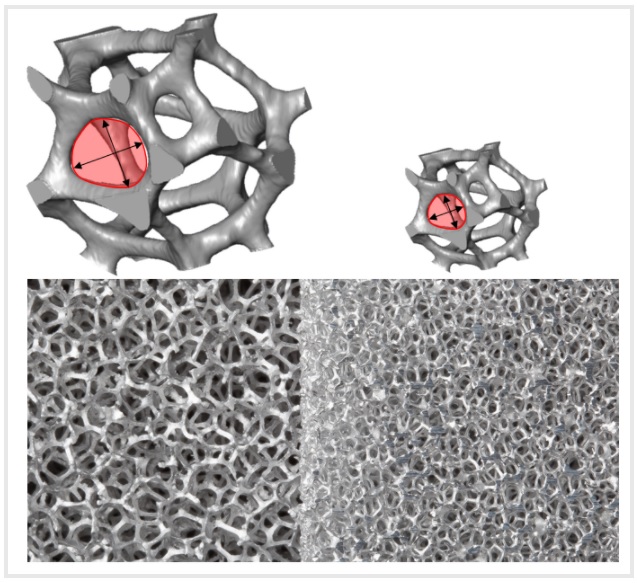

The openness of the structure is largely driven by pore size. ERG uses a term called Pores Per Inch (PPI) to classify the pore size of a Duocel® foam structure. These PPI designations roughly equate to the number of pores aligned on a linear inch of the structure.

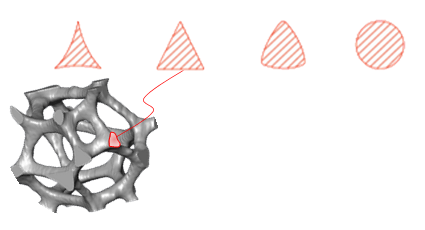

Each cell in the structure is typically a 14-faceted polyhedral framed by solid ligaments with each face being an open pore. Using a soccer ball as an analogy for a cell within a foam structure, the pores are like the patches on the ball; the larger each patch, the larger the whole soccer ball (or cell) will be.

The pore size drives the surface area to volume ratio. This is extremely important for air oil separators, heat exchangers, and electrodes where it is ideal to maximize the foam’s interaction area, allowing for more compact designs.

Relative Density

The third major variable used to control the performance of the open-celled foam structure is the ligament cross section, which is specified with a term called Relative Density. Especially for metal foams, the ability to vary the cross section of the ligament is unique to ERG’s Duocel® and has a significant impact on the structure’s strength. The larger the ligament cross section (higher relative density), the stronger the structure is.

ERG classifies this relative density parameter as a percentage, or volume fraction, of the material within the foam’s ligaments compared to the entire bulk volume that the structure takes up. Relative density is often thought of as the inverse of porosity, because it represents the amount of material in the structure rather than the void space.

With relative density driving the strength and conductivity of the structure, it is an important parameter to control for applications such as structural elements, energy absorbers, and heat exchangers.

Why ERG?

ERG has been manufacturing Duocel® foams in the USA since 1967. The proprietary manufacturing process has been optimized to deliver high quality foam structures. ERG has amassed a database of material properties including extensive micro-CT scan data. The images below show an example of the material properties that can be extracted from CT scan data. With just the three basic variables, the possible foam configurations are limitless; ERG’s design and development experience can narrow down the right material solution for a range of applications.